Packaging Innovations

R&D that sets us apart

Interaction, ideas and innovation: the driving force behind our business.

As the market landscape for our customers continues to change and evolve, future thinking has never been more important. It’s why we invest in a creative, collaborative culture and in environments where our research and development (R&D) teams, packaging professionals and multi-discipline experts can work side by side to invent and test tomorrow’s exciting products and solutions, from pressure sensitive labels, to shrink sleeves.

What’s more, our manufacturing expertise and broad product portfolio deliver tailored solutions that are cost-effective as well as fit for purpose – from food packaging and medical blister packs to credit cards.

As the market landscape for our customers continues to change and evolve, future thinking has never been more important. It’s why we invest in a creative, collaborative culture and in environments where our research and development (R&D) teams, packaging professionals and multi-discipline experts can work side by side to invent and test tomorrow’s exciting products and solutions, from pressure sensitive labels, to shrink sleeves.

What’s more, our manufacturing expertise and broad product portfolio deliver tailored solutions that are cost-effective as well as fit for purpose – from food packaging and medical blister packs to credit cards.

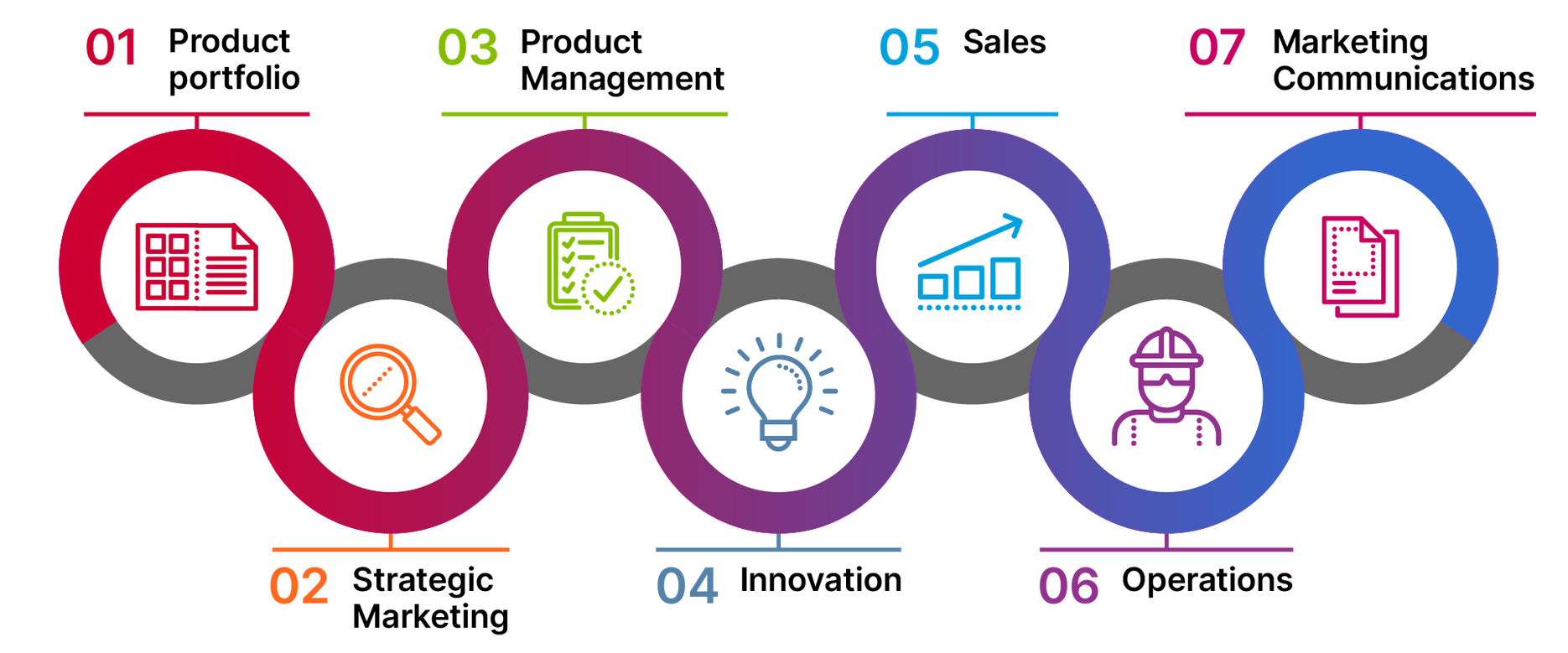

From idea to solution: Our marketing and innovation process

Co-creating packaging solutions of the future

The kp i.center in Charlottesville, USA, is one of the industry’s first packaging technology centres. It is a leading-edge collaborative space where we work with customers, especially those without their own in-house capacity, to develop solutions for their packaging needs.

The centre was established to meet the needs of global pharmaceutical packaging professionals, including those in operations, marketing and procurement, for both branded and generic products.

Ideas flow freely in an open and welcoming environment where packaging professionals can immerse themselves in idea sharing with kp’s expert packaging design engineers. These facilities have led to the discovery of innovative new packages and optimised prototypes, and helped customers to rapidly prototype new products.

Working with the kp team, customers can use the in-house demo facility to test and assess designs in real time. This cooperative approach can greatly reduce the time taken to design and choose packaging, reducing costs and shortening product-to-market release.

The centre was established to meet the needs of global pharmaceutical packaging professionals, including those in operations, marketing and procurement, for both branded and generic products.

Ideas flow freely in an open and welcoming environment where packaging professionals can immerse themselves in idea sharing with kp’s expert packaging design engineers. These facilities have led to the discovery of innovative new packages and optimised prototypes, and helped customers to rapidly prototype new products.

Working with the kp team, customers can use the in-house demo facility to test and assess designs in real time. This cooperative approach can greatly reduce the time taken to design and choose packaging, reducing costs and shortening product-to-market release.

Innovation @kp FP is shaping the future

We invest millions each year in scientific discovery, testing and developing materials to create new functionalities, design and sustainable alternatives for our high-performance, complex structures.

Our four FP innovation hubs in Pontivy (FR), Featherstone (UK), Pravia (ES) and Girona (ES), work closely with our customers to shape the future of packaging design.

Our four FP innovation hubs in Pontivy (FR), Featherstone (UK), Pravia (ES) and Girona (ES), work closely with our customers to shape the future of packaging design.

R&D funded projects

The unique FOX approach researches and develop innovative, small scale technologies in mobile or flexible processing units for different applications for small and medium enterprises and farmers in the fruit and vegetable sector in Europe. This will stimulate the transition from a centralised industry to regional hubs that employ innovative, flexible and sustainable technologies based on seasonality and demand. By this, FOX meets expectation of small food businesses for innovative processing solutions, technically and economically feasible, that also consider needs of the food chain and consumers. Consumers expect food they can trust, natural as possible. FOX focuses on mild processing technologies: low temperature drying, mild extraction, mild preservation with pulsed electric field or high pressure, innovative conditioning and packaging and rapid quality testing. By this a variety of fruit/vegetable products can be produced with superior physical and nutritional quality and so contributing to a healthier food diet.

Fresh fruits and vegetables are the basis of a healthy diet, so it is important to encourage their consumption by providing new and more attractive formats and recipes that are adapted to the different consumer groups (infants, adult) and today’s consumption habits. To meet these needs, the work will focus on developing innovative quality analysis and new sustainable conditioning and packaging systems for snacks made from complex mixes of fresh fruits and vegetables. This implies different challenges, like proper analysis of the products and consideration fo their very complex ripening mechanism (product mix). To overcome these challenges, the research will focus on innovative and flexible packaging technologies based on a two-stage approach: (i) analysis of product quality by quick mobile methods (mobile spectroscopy, quality evaluation, respiration intensity), and (ii) modificaiton of the conditioning and packaging process. New sustainable primary packaging systems based on the measured product quality and different rates of the products respiration using micro-perforated packaging or perm-selective films will be developed as well as a new sustainable material for the secondary packaging to be used through the e-commerce distribution chain. This will result in a mobile and sustainable system for analyzing, conditioning and packaging of fresh fruit and vegetable snacks.

https://www.fox-foodprocessinginabox.eu/

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 817683

Fresh fruits and vegetables are the basis of a healthy diet, so it is important to encourage their consumption by providing new and more attractive formats and recipes that are adapted to the different consumer groups (infants, adult) and today’s consumption habits. To meet these needs, the work will focus on developing innovative quality analysis and new sustainable conditioning and packaging systems for snacks made from complex mixes of fresh fruits and vegetables. This implies different challenges, like proper analysis of the products and consideration fo their very complex ripening mechanism (product mix). To overcome these challenges, the research will focus on innovative and flexible packaging technologies based on a two-stage approach: (i) analysis of product quality by quick mobile methods (mobile spectroscopy, quality evaluation, respiration intensity), and (ii) modificaiton of the conditioning and packaging process. New sustainable primary packaging systems based on the measured product quality and different rates of the products respiration using micro-perforated packaging or perm-selective films will be developed as well as a new sustainable material for the secondary packaging to be used through the e-commerce distribution chain. This will result in a mobile and sustainable system for analyzing, conditioning and packaging of fresh fruit and vegetable snacks.

https://www.fox-foodprocessinginabox.eu/

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 817683

The CEUS project researches and tests new treatments that can transform and create value from domestic plastic waste for the first time. Different types of domestic waste mixed together present a major challenge when classifying, sorting, during treatment, and transformation. Working on CEUS alongside kp are several companies across the full value chain: URBASER for waste management, ACTECO as a recycler, and converters PICDA, NORTPALET and ERUM. The CEUS project is funded by the working framework CIEN of CDTI (Spanish Ministry of Science and Innovation) and co-funded by the European Regional Development Fund (ERDF).

YPACK is an EU-funded project with a total duration of 36 months. The project aims to scale up and validate two innovative food packaging solutions based on polyhydroxyalkanoates (PHA) with active properties and passive barrier to reduce food waste by prolonging food shelf life.

There is an increasing awareness of the need to develop innovative packaging materials that maintain or extend the shelf life of foodstuffs to reduce food waste and minimize the environmental footprint of packaging materials.

The ideal packaging involves lower carbon and water footprints, is biodegradable and/or compostable, makes use of wastes or by-products, is properly eco-designed, safe and has the right preservation properties to minimize food waste.

YPACK, a 3-year EU-funded project will use a holistic approach and methodology involving different knowledge areas to produce the appropriate packaging solution:

• Development of packaging solutions (Production of PHBV layers, compounding, prototyping, Industrial Validation)

• Product Validation (Quality / Shelf life)

• Social approach (Customer profiling, Dissemination, Policies & Regulatory)

• Market Assessment (Business study and Risk assessment)

YPACK will scale up production and commercially validate two innovative food packaging solutions based on polyhydroxyalkanoate (PHA). The new packaging will make use of food industry by-products (cheese whey and almond shells) assure the biodegradability and recyclability, and reduce food waste, in the frame of the EU Circular Economy strategy. A rough estimate shows that an improvement of shelf life by 20% and 50% respectively, has a potential to reduce food waste with 12.5% to 30% respectively.

Specifically, YPACK will develop a:

• Fully renewable flow pack film

• Fully compostable tray

The validity of these two packaging solutions will be assessed in fresh products (meat, fruits & vegetables and fresh pasta), which are the most significant contributors to food waste. A consumer profiling and market study will be performed to identify consumers ́ preferences and market needs, and match them with the new EU regulations and packaging materials development.

www.ypack.eu

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 773872.

There is an increasing awareness of the need to develop innovative packaging materials that maintain or extend the shelf life of foodstuffs to reduce food waste and minimize the environmental footprint of packaging materials.

The ideal packaging involves lower carbon and water footprints, is biodegradable and/or compostable, makes use of wastes or by-products, is properly eco-designed, safe and has the right preservation properties to minimize food waste.

YPACK, a 3-year EU-funded project will use a holistic approach and methodology involving different knowledge areas to produce the appropriate packaging solution:

• Development of packaging solutions (Production of PHBV layers, compounding, prototyping, Industrial Validation)

• Product Validation (Quality / Shelf life)

• Social approach (Customer profiling, Dissemination, Policies & Regulatory)

• Market Assessment (Business study and Risk assessment)

YPACK will scale up production and commercially validate two innovative food packaging solutions based on polyhydroxyalkanoate (PHA). The new packaging will make use of food industry by-products (cheese whey and almond shells) assure the biodegradability and recyclability, and reduce food waste, in the frame of the EU Circular Economy strategy. A rough estimate shows that an improvement of shelf life by 20% and 50% respectively, has a potential to reduce food waste with 12.5% to 30% respectively.

Specifically, YPACK will develop a:

• Fully renewable flow pack film

• Fully compostable tray

The validity of these two packaging solutions will be assessed in fresh products (meat, fruits & vegetables and fresh pasta), which are the most significant contributors to food waste. A consumer profiling and market study will be performed to identify consumers ́ preferences and market needs, and match them with the new EU regulations and packaging materials development.

www.ypack.eu

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 773872.

The goal of this R&D project is to investigate various decontamination existing and novel technologies required to guarantee food safety during manufacturing of food packaging that contains post-consumer recycled material from food packaging as well.

Food packaging trays become incorporated into a new product on the market thus demonstrating that the food trays are recyclable and incorporate their own recycled material in post-consumer environments. The technical novelty is to carry it out in direct contact with food, since currently, to guarantee food safety, it is carried out in sandwich-type multilayer structures where the outer layer is made of virgin material. A 100% recycled tray containing material from trays is currently a technological challenge that BARYR project aims to overcome due to the presence of multilayer materials, labels, absorbents, paper, inks, other polymers, additives, gas barriers, etc.

BARYR project addresses existing technological challenges:

This project has received funding from the IDEPA and ERDF for the execution of research and development projects in the Principality of Asturias during 2020 call.

Food packaging trays become incorporated into a new product on the market thus demonstrating that the food trays are recyclable and incorporate their own recycled material in post-consumer environments. The technical novelty is to carry it out in direct contact with food, since currently, to guarantee food safety, it is carried out in sandwich-type multilayer structures where the outer layer is made of virgin material. A 100% recycled tray containing material from trays is currently a technological challenge that BARYR project aims to overcome due to the presence of multilayer materials, labels, absorbents, paper, inks, other polymers, additives, gas barriers, etc.

BARYR project addresses existing technological challenges:

- Regarding post-consumer sorting and streams commercializing recycled raw materials from food trays

- About decontamination technologies existing and under development

- To achieve containers with benefits similar to those currently provided in terms of mechanical and thermal resistance and optical properties

- On food safety: guaranteeing compliance current European regulation

- On sustainability and recyclability: verifying that the materials recycled are technically and economically viable and can maintain a supply over time, as well as that the containers made with them are recyclable as well

In addition, this project aligns with strategic guides established by both the European Commission, The Spanish Ministry for the Ecological Transition and the regional initiatives of the Principality of Asturias regarding the requirement to place recycled and recyclable packaging on the market with the objective of minimizing the waste generated by consumers.

This project has received funding from the IDEPA and ERDF for the execution of research and development projects in the Principality of Asturias during 2020 call.

Currently, mechanical recycling technologies are not sufficient for the recovery of all PET used in food containers and its subsequent incorporation into new food packaging containers. The main challenge is the need to use complex multilayer materials that, together with additives, inorganic fillers, dyes, inks, adhesives, and other substances, make it unfeasible to obtain RPET with sufficient purity and quality.

That is why it is necessary to develop chemical recycling technologies, and those based on glycolysis are of special interest. However, there is limited knowledge about which packaging materials can provide viable performance both economically and in terms of quality.

kp investigates the criteria to be considered in the formulations of the starting packaging materials to facilitate their recovery through chemical recycling.

MAIN OBJECTIVES ADDRESSED:

This project has received funding from the IDEPA and ERDF for the execution of research and development projects in the Principality of Asturias during 2021 call.

That is why it is necessary to develop chemical recycling technologies, and those based on glycolysis are of special interest. However, there is limited knowledge about which packaging materials can provide viable performance both economically and in terms of quality.

kp investigates the criteria to be considered in the formulations of the starting packaging materials to facilitate their recovery through chemical recycling.

MAIN OBJECTIVES ADDRESSED:

- Development of RPET containers manufactured using properly structured polyester compounds to facilitate their recycling through chemicals.

- Evaluation of the effects of incorporating PET/PE, PET/EVOH/PE, GPET multilayers in the process for obtaining BHET by glycolysis

- Evaluation of the presence of additives, dyes, inks and inorganic fillers

- Incorporation of RPET pellets obtained chemically in new containers for food use.

- Evaluation of the alimentary aptitude of the new containers

This project has received funding from the IDEPA and ERDF for the execution of research and development projects in the Principality of Asturias during 2021 call.

Other funded projects

The BALOOP project is supporting kp in further developing its commitment to circularity at its packaging site in Pravia, Spain. The project is funded by IDEPA in the Principality of Asturias, Spain, and is co-funded by European Just Transition Fund. It is contributing to kp achieving its sustainability objectives, as set out in its "Investing in better" strategy.

Using recycled material from PET trays in new trays for food use, ensuring food safety, preserving freshness and increasing the shelf life of food and contributing to the reduction of food waste.

Influencing the entire value chain to generate more demand. At the same time, strengthening partnerships with recycling companies, suppliers and customers to ensure a steady supply of post-consumer recycled plastic from trays.

Driving social change to improve collection and invest in new sorting and recycling technologies.

This investment is key in the manufacture of the new ranges of trays to meet sustainability objectives such as kp Tray2Tray®, kp Elite® or kp Zapora®.

Using recycled material from PET trays in new trays for food use, ensuring food safety, preserving freshness and increasing the shelf life of food and contributing to the reduction of food waste.

Influencing the entire value chain to generate more demand. At the same time, strengthening partnerships with recycling companies, suppliers and customers to ensure a steady supply of post-consumer recycled plastic from trays.

Driving social change to improve collection and invest in new sorting and recycling technologies.

This investment is key in the manufacture of the new ranges of trays to meet sustainability objectives such as kp Tray2Tray®, kp Elite® or kp Zapora®.

This offers customers a sustainable choice, and enables them to showcase their products in quality packaging and advance their own sustainability goals. This demonstrates the competitive advantage of PET compared to other alternatives which do not meet the criteria of being both recyclable and incorporating recycled content, ensuring circularity.