Close the Loop

Closing the loop requires us to design for recyclability, maximise post-consumer recycled content (PCR) quality and availability, and to work with industry stakeholders on policy, consumer education and planning to ensure suitable infrastructure is available.

We must also consistently upgrade and re-engineer our production processes to maximise the amount of PCR we’re able to use.

We must also consistently upgrade and re-engineer our production processes to maximise the amount of PCR we’re able to use.

Highlights in 2024

24.4%

24.4% of the plastic packaging we produced last year comprised postconsumer recycled (PCR) material.

12.5%

12.5% of our recycled material was from kp Tray2Tray®.

68%

Recyclable alternatives offered for 68% of our product portfolio.

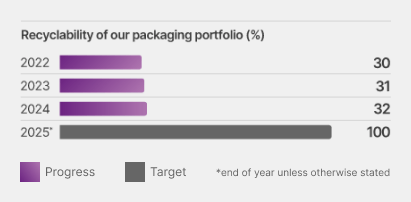

32%

32% of our products by volume are designed for recyclability (2019: 22%).Target I: Use more recycled material

We will use at least 30% post-consumer recycled (PCR) material in our packaging.

Highlights

Our use of PCR has remained stable, attributable to continued process optimisation. Market fluctuations challenged the industry on PCR usage and availability.Future outlook

We remain focused on developing new films for novel packaging that include PCR, while also expanding the use of recycled materials with the aim of keeping material flows inside a closed loop.

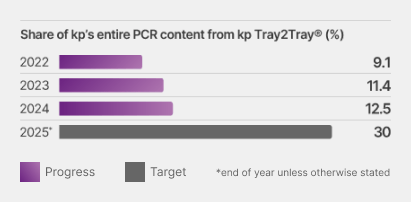

Target II: Close the packaging loop

At least 30% of the PCR material in our packaging will be from the kp Tray2Tray® initiative.

Highlights

We continue to grow the share of kp Tray2Tray® despite market challenges. This is thanks to our strong partnerships across the value chain.Future outlook

We have made significant progress on the journey to originate 30% of our PCR consumption from pots, tubs and trays by 2025. However, the challenges in securing supplies of good-quality tray flake are limiting our ability to progress at the expected pace. Strong collaborations are key to stable supply, and we are committed to doing more as soon as we’re able to.Target III: Recyclability

100% of our packaging will be recyclable.