Recycling of PET food trays – key focus at major industry conferences

One of the best ways of making progress in food packaging sustainability is to gather leading voices in a room, and simply talk. The packaging industry is so wide and varied that most businesses approach the topic with different perspectives and insights, which makes knowledge sharing even more important.

Over the summer, members of the kp team actively participated in two significant industry conferences, sharing perspectives on the challenges of PET (Polyethylene Terephthalate) recycling, and the opportunities that lie ahead on the path to a circular economy in food packaging trays.

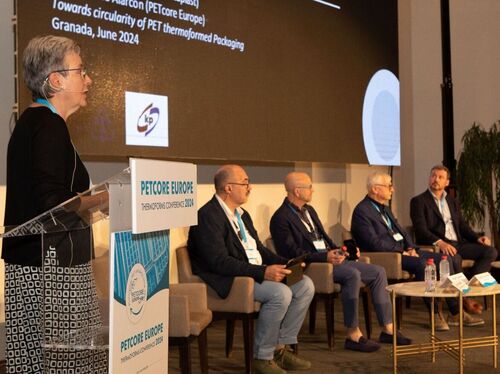

At the Thermoforms Conference 2024 and the Plastics Recycling Show Europe, kp FP’s Ana Fernandez, Senior Technical Advisor, and Samuel Pardo, Senior Innovation Manager, highlighted the path towards circularity and the challenges and opportunities in achieving recycled content targets.

Over the summer, members of the kp team actively participated in two significant industry conferences, sharing perspectives on the challenges of PET (Polyethylene Terephthalate) recycling, and the opportunities that lie ahead on the path to a circular economy in food packaging trays.

At the Thermoforms Conference 2024 and the Plastics Recycling Show Europe, kp FP’s Ana Fernandez, Senior Technical Advisor, and Samuel Pardo, Senior Innovation Manager, highlighted the path towards circularity and the challenges and opportunities in achieving recycled content targets.

Share this story

The scale of PET tray waste and the need for industry-wide collaboration

At present, when PET trays go into the recycling loop, the material is too often lost to lower-value secondary products, rather than creating more food-safe trays. As a result, this valuable material becomes downcycled.

At both events, a key talking point was the importance of standardisation when it comes to PET tray recycling processes and further closing the loop. Achieving this involves the establishment and enforcement of fully implemented Design for Recycling (D4R) guidelines and common standards across the European Union. Where international recycling programmes have often been fractured and inconsistent from one geography to the next, a unified approach is crucial for ensuring that recycled PET trays can be reintegrated seamlessly into the production cycle. This will reduce reliance on virgin PET materials.

Ensuring traceability and transparency

Full traceability and transparency are essential in the introduction of recycled PET from trays and in the management of PET waste generated for subsequent recycling. When the packaging is food-contact specified, this is not just important but essential.

The incoming PPWR (Packaging and Packaging Waste Regulation) changes in the EU are welcomed, as they are set to bring harmonisation and a competitive level playing field for the packaging market in all countries.

To meet the ambitious recycling targets set by the PPWR, it is vital that collection rates increase. New streams of material that are not currently collected and recycled, need to be developed or alternatively, recycled content originating from outside the EU will be required. In the latter case, we must ensure full traceability of material origin. It is estimated that PPWR targets will demand at least 500-600k tonnes of post-consumer recycled (PCR) material in PET trays by 2040.

The certification and guarantee of origin for imported recycled materials were highlighted as significant concerns. The high risk associated with importing overseas recycled material lies in the difficulty of verifying its quality and compliance with EU standards. Robust verification methods and international cooperation are vital to address these challenges and integrate imported recycled content effectively.Addressing total cost of ownership and consumer education

Reducing the total cost of ownership through incentives that promote a circular economy is a vital step towards the widespread adoption of rPET trays and making an impact in the long-term. Additionally, improving communication and consumer education on the household separation of waste is essential to support recycling efforts around the world.

As discussed by attendees at both events, this involves comprehensive efforts to educate consumers about the importance of recycling and the specific steps they can take to ensure their waste is correctly sorted and processed. Enhancing consumer participation can significantly improve the quality of recyclable materials and increase recycling rates.

Challenges in harmonisation of recycled content

One of the significant challenges discussed was the certification of recycled content and the standardisation of the criteria defining what constitutes recycled content. The industry faces difficulties in establishing uniform standards that are accepted globally, which complicates the certification process. There are ongoing efforts to create a consistent framework that will streamline certification and ensure that recycled content is verified and trusted across the market.

Additionally, the application and certification of the mass balance ‘fuel exempt’ condition were topics of interest. This approach involves a controlled blending process to ensure that the recycled content meets the necessary standards without compromising quality. The mass balance method requires meticulous monitoring and certification to guarantee that the final products meet regulatory and consumer expectations.

Additionally, the application and certification of the mass balance ‘fuel exempt’ condition were topics of interest. This approach involves a controlled blending process to ensure that the recycled content meets the necessary standards without compromising quality. The mass balance method requires meticulous monitoring and certification to guarantee that the final products meet regulatory and consumer expectations.

Our kp Elite® fully recyclable trays combined with kp FlexiLid® EH 145 R offer a perfect solution to increase the amount of good recycling feedstock in the stream. Both are fully recyclable.

Innovating with kp and strategic partnerships

During the presentations, Samuel and Ana referred to several kp innovations that seek to shape the future of food tray packaging.

Technological innovation and strategic partnerships are at the heart of kp’s approach to driving circularity in PET packaging. The kp Tray2Tray® initiative exemplifies this, aiming to increase the use of recycled tray flake and reduce reliance on virgin materials.

Through initiatives like kp Tray2Tray®, kp is on a mission to recover used food packaging and turn it back into more of the same, ensuring our products meet the highest standards of recyclability. In 2023 11.4% of the recycled material used came from kp Tray2Tray®. The goal is to continually increase that share. The kp Tray2Tray® initiative involves strategic collaborations with recyclers, packers, and retailers to boost the collection and processing of PET trays.

Technological innovation and strategic partnerships are at the heart of kp’s approach to driving circularity in PET packaging. The kp Tray2Tray® initiative exemplifies this, aiming to increase the use of recycled tray flake and reduce reliance on virgin materials.

Through initiatives like kp Tray2Tray®, kp is on a mission to recover used food packaging and turn it back into more of the same, ensuring our products meet the highest standards of recyclability. In 2023 11.4% of the recycled material used came from kp Tray2Tray®. The goal is to continually increase that share. The kp Tray2Tray® initiative involves strategic collaborations with recyclers, packers, and retailers to boost the collection and processing of PET trays.

As a clearer route to tray circularity lies ahead, driven by innovation from packaging innovators like kp, it is vital that discussions continue. kp’s presentations at these summer conferences underscore the critical need for industry-wide collaboration, innovation, and stringent regulatory frameworks to achieve circularity in PET tray packaging.