Why kp Elite®’s patent win ensures trust, quality, and supply chain confidence in MAP trays

At kp, we have cemented our position as a technological leader in the packaging industry after our patent claims for the groundbreaking kp Elite® tray were upheld by the European Patent Office (EPO) Board of Appeal.

Patent protection means that we have patent claims covering our unique Elite® mono-MAP tray structure, with such claims being upheld in a final decision by the European Patent Office Board of Appeals, providing greater compatibility with European recycling infrastructure without compromising sealing or shelf-life performance. This is huge news for kp as a business, and it’s great news for our customers and partners, too.

Below, we’ll unpack why this is so important for kp, our customers, and the wider plastics industry.

Below, we’ll unpack why this is so important for kp, our customers, and the wider plastics industry.

Share this story

What is kp Elite®?

kp Elite® is a best-in-class thermoformed mono tray for modified atmosphere pack (MAP) applications. It was designed with fresh protein in mind, but it can be used across any food application that requires MAP.

First launched commercially in 2014, it’s circular by design and endorsed by Petcore Europe’s Tray Circularity Evaluation Platform (TCEP). Made with up to 100% recycled post-consumer PET, which is itself recyclable, kp Elite® brings productivity and cost-saving benefits compared to rPET/PET and rPET mono alternatives.

First launched commercially in 2014, it’s circular by design and endorsed by Petcore Europe’s Tray Circularity Evaluation Platform (TCEP). Made with up to 100% recycled post-consumer PET, which is itself recyclable, kp Elite® brings productivity and cost-saving benefits compared to rPET/PET and rPET mono alternatives.

You can visit our dedicated product page to learn more about kp Elite®.

What makes kp Elite® unique?

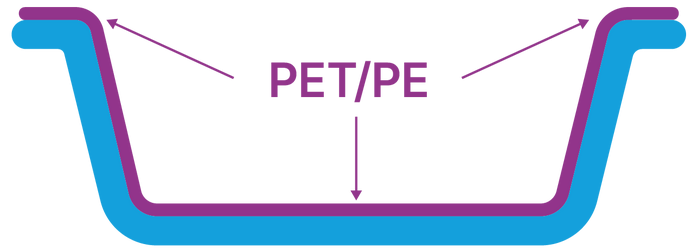

The tray is set apart from traditional alternatives by its structure. Like most MAP trays for fresh protein, kp Elite® is a thermoformed container designed with a base and a continuous side wall. The upper edge of the side wall is formed into a peripheral flange to aid with sealing. Where kp’s innovation is a step up from the norm is in its sealing layer.

In traditional plastic MAP trays, a layer of PE film is laminated across the entire surface area of the tray interior, to provide a suitable base for the lidding film to adhere to in the packaging and filling process. kp Elite® instead replaces this PE film layer with a hot melt adhesive applied just to the sealing flange, which results in less overall material use in the tray (no PE film), and cuts waste and the total cost of ownership of each and every tray.

In traditional plastic MAP trays, a layer of PE film is laminated across the entire surface area of the tray interior, to provide a suitable base for the lidding film to adhere to in the packaging and filling process. kp Elite® instead replaces this PE film layer with a hot melt adhesive applied just to the sealing flange, which results in less overall material use in the tray (no PE film), and cuts waste and the total cost of ownership of each and every tray.

kp Elite® replaced the PE layer with a hot melt adhesive only in the tray sealing flange

While sounding like a simple solution, significant research and development went into the flange sealing process, with numerous application process developments being trialled, until the perfect sealing performance was determined and patented accordingly.

Today, combined with the many other benefits of the kp Elite® tray solution, including exceptional clarity for consumers and improved production uptime for packers and processors, this structure marks it out as the best-in-class for mono-MAP tray applications.

Today, combined with the many other benefits of the kp Elite® tray solution, including exceptional clarity for consumers and improved production uptime for packers and processors, this structure marks it out as the best-in-class for mono-MAP tray applications.

What this means for you

Your business deserves the best – and now, when you look for kp Elite®, you know you’re getting it. Accept no imitations.

Having our patent claims upheld highlights kp as the leader in the rigid, flexible, and specialty film segments. At a time when supply chains are under closer scrutiny than ever thanks to legislation like the EU Deforestation Regulation (EUDR) and the Corporate Sustainability Due Diligence Directive (CSDDD), businesses need to know they can trust their packaging lines.

Even better, kp Elite® enables customers to streamline supply chains by bundling together our tray and lidding film solutions. Get everything you need for the highest quality all-in-one MAP tray and lidding solution from a single, market-leading supplier, and buy with confidence a legally protected, top-of-the-line innovation.

We have successfully defended our IP and continue to guarantee the highest standards of performance, reliability, and quality that our customers rightly expect.

We’re proud to be playing a leading role in driving the plastics industry towards true circularity. This news is just the latest step on that journey.

To learn more about kp Elite® and our range of industry-leading innovations, request a sample or get in touch with our customer service experts today.

Having our patent claims upheld highlights kp as the leader in the rigid, flexible, and specialty film segments. At a time when supply chains are under closer scrutiny than ever thanks to legislation like the EU Deforestation Regulation (EUDR) and the Corporate Sustainability Due Diligence Directive (CSDDD), businesses need to know they can trust their packaging lines.

Even better, kp Elite® enables customers to streamline supply chains by bundling together our tray and lidding film solutions. Get everything you need for the highest quality all-in-one MAP tray and lidding solution from a single, market-leading supplier, and buy with confidence a legally protected, top-of-the-line innovation.

We have successfully defended our IP and continue to guarantee the highest standards of performance, reliability, and quality that our customers rightly expect.

We’re proud to be playing a leading role in driving the plastics industry towards true circularity. This news is just the latest step on that journey.

To learn more about kp Elite® and our range of industry-leading innovations, request a sample or get in touch with our customer service experts today.

More like this