Work Smarter

Working smarter is about operational excellence in energy management, reducing greenhouse gas (GHG) emissions and sending zero waste to landfill.

Customers and society are demanding energy efficiency wherever possible, and in a year where our demands have been stable, we have used less energy to make our products. This has been particularly crucial in light of recent security of supply issues and attendant high costs.

Customers and society are demanding energy efficiency wherever possible, and in a year where our demands have been stable, we have used less energy to make our products. This has been particularly crucial in light of recent security of supply issues and attendant high costs.

Highlights in 2024

-19%

Overall energy use has fallen 19% since 2019.

52%

52% reduction in operational greenhouse gas emissions since 2019.Zero

Our sites continue to send zero waste to landfill1.63%

63% global renewable electricity procurement across all geographies.1 Where legislation allows

Target I: Improve energy efficiency

We will increase energy efficiency by 17% against a 2019 baseline.

Highlights

We saw minimal increase in energy intensity compared with previous years.Future outlook

We have a very strong foundation in terms of energy efficiency, and our team will continue to make improvements. The way we organise our energy-efficiency projects will evolve, building on previous successes.

Target II: Reduce carbon emissions

We will reduce Scope 1 and 2 emissions by 50%, and by 2030 Scope 3 emissions by 20% per tonne of raw materials, against a 2019 baseline.

Highlights

We have achieved our Scope 1 and 2 emissions goal one year ahead of schedule by increasing our mix of renewable energy. We continued to partner with our suppliers to decarbonise the value chain.Future outlook

We are working on a new set of goals, which will include ambitious carbon targets. Renewable energy and collaboration with our suppliers will be critical.

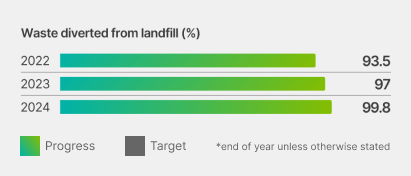

Target III: Stop sending waste to landfill

We will send zero waste to landfill or incineration without energy recovery**

Highlights in 2023

We’ve made significant progress and have now achieved zero waste to landfill in our sites, where legally possible.Future outlook

We will work hard to protect and build on this achievement, and to reduce the total amount of waste produced in our operations, which we are looking at reducing by a further 5% by the end of 2024.

** Where legislation allows.